Inicio » Sistemas de envasado BELCA » Máquinas de envasado » Termoformadoras Belca

La gama de Termoformadoras BELCA se compone de máquinas especialmente diseñadas para el formado de bandejas y sellado para productos de alimentación partiendo de dos láminas de film. Con carga manual o alimentación automática y preparadas para envase bajo MAP, vacío o skin.

Haga click en las imágenes para ver más información sobre el modelo.

Stock permanente

de recambios

Líder en servicio

de repuestos urgente

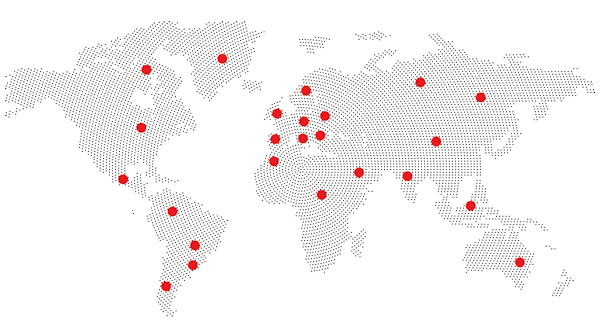

+5.000 instalaciones

en todo el Mundo

SAT Líder

del mercado

Si lo prefieres, llámanos y resolveremos tus dudas de viva voz:

Nuestras Soluciones de Envasado están presentes en todo el mundo

Especificaciones orientativas, pueden no estar actualizadas. Por favor, solicite más información mediante el formulario de contacto.